SaniLine®

Our CIPP inversion installation process for trenchless rehabilitation of pressurized water, gas, petrol, oil and heating mains.

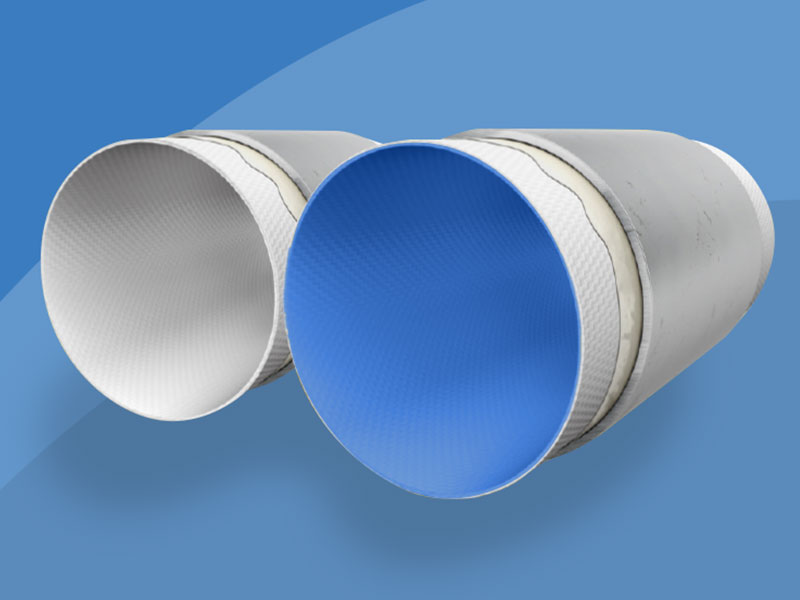

SaniLine® is ideally suited for the rehabilitation of all common types of pipes, including cast-iron, ductile iron, steel, PVC as well as asbestos-cement pipes, and media with diameters ranging from DN80 to DN 800. Available with polyethylene (PE) and polyurethane (PU) coatings.

Benefits

- Minimisation of down times and traffic obstruction due to fast rehabilitation of extremely long installation lengths of up to 350m, including bends of up to 90°

- Extremely cost efficient installation process

- Low civil engineering works

- Reduced digging, low logistics costs and no need for expensive special installation equipment due to ambient curing

- Increased network efficiency through enhanced conductibility (K value)

- Age tested to show no deterioration of over 50 years

- 100% epoxy-free installation process – no bisphenol A/F

SaniLine® consists of an extremely strong textile liner with thermoplastic coating and a two-component polyurethane adhesive, connecting the liner to the old pipe. After cleaning the pipe, the liner is filled with adhesive and wound into the pressure box, before it is inverted into the main using compressed air. In the end of the inversion process, a final pressure test is conducted and both ends are sealed using AMEX-10 Liner End Seals.

The ambient curing resin system of SaniLine® requires only a pressure drum for installation, limiting the space and equipment. Avoiding heating for water or steam curing, reduces the energy consumption to a minimum.

| Pressure | Water, petrol, oil and heating: up to 16 bar / Gas 5 bar |

| Temperature | Water, petrol, oil, heating: up to 70ºC / Gas: up to 80ºC |

| Material | Liner: circular-woven hose made by 100% polyester fibers |

| Coating: extruded, thermoplastic polyurethane and polyethylene |

Exact specifications and characteristics always depend on the specific application and medium.

| Tensile strength, longitudinal | 1000-1500 N/cm |

| Tensile strength, radial | 800-2000 N/cm |

| Elongation at break, longitudinal | 20-25% |

| Elongation at break, radial | 40-50% |

| Wall thickness | 1.5 - 3.2 mm |

| Diameter | 80 - 800 mm |

| max. product length | 700 - 1000 m |

| max. installation length | up to 350 m |

SaniLine® Installation & Engineering.

Systems for Engineering.

SaniLine® is inverted by compressed air using the pressure drum system. The high strength textile limits the wall thickness to a maximum of 3.5mm, providing very long installation lengths of up to 350m. After the inversion process is completed, the drum can be disconnected.

The SaniLine® is completely sealed and the pressure is maintained without external pressure sources. The section is closed with a gate valve directly connected to the liner. The curing process is documented by a data logger for the pressure.